LASERSYSTEMEN UIT NEDERLAND

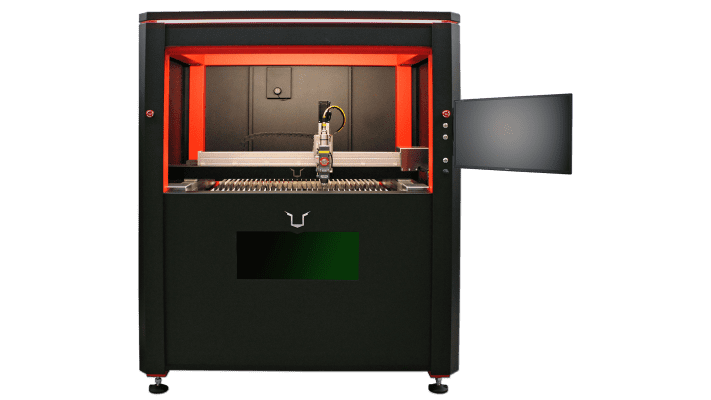

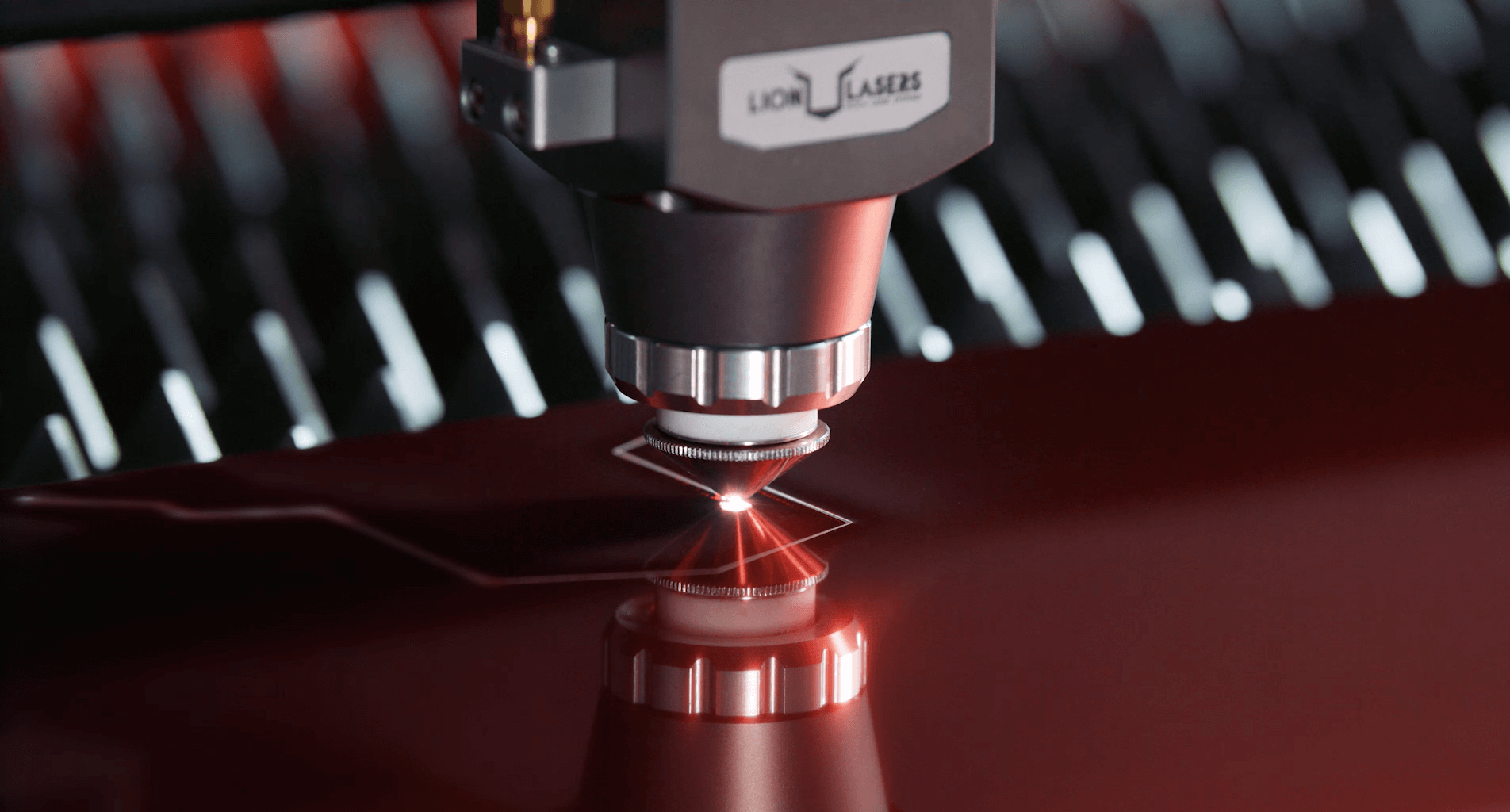

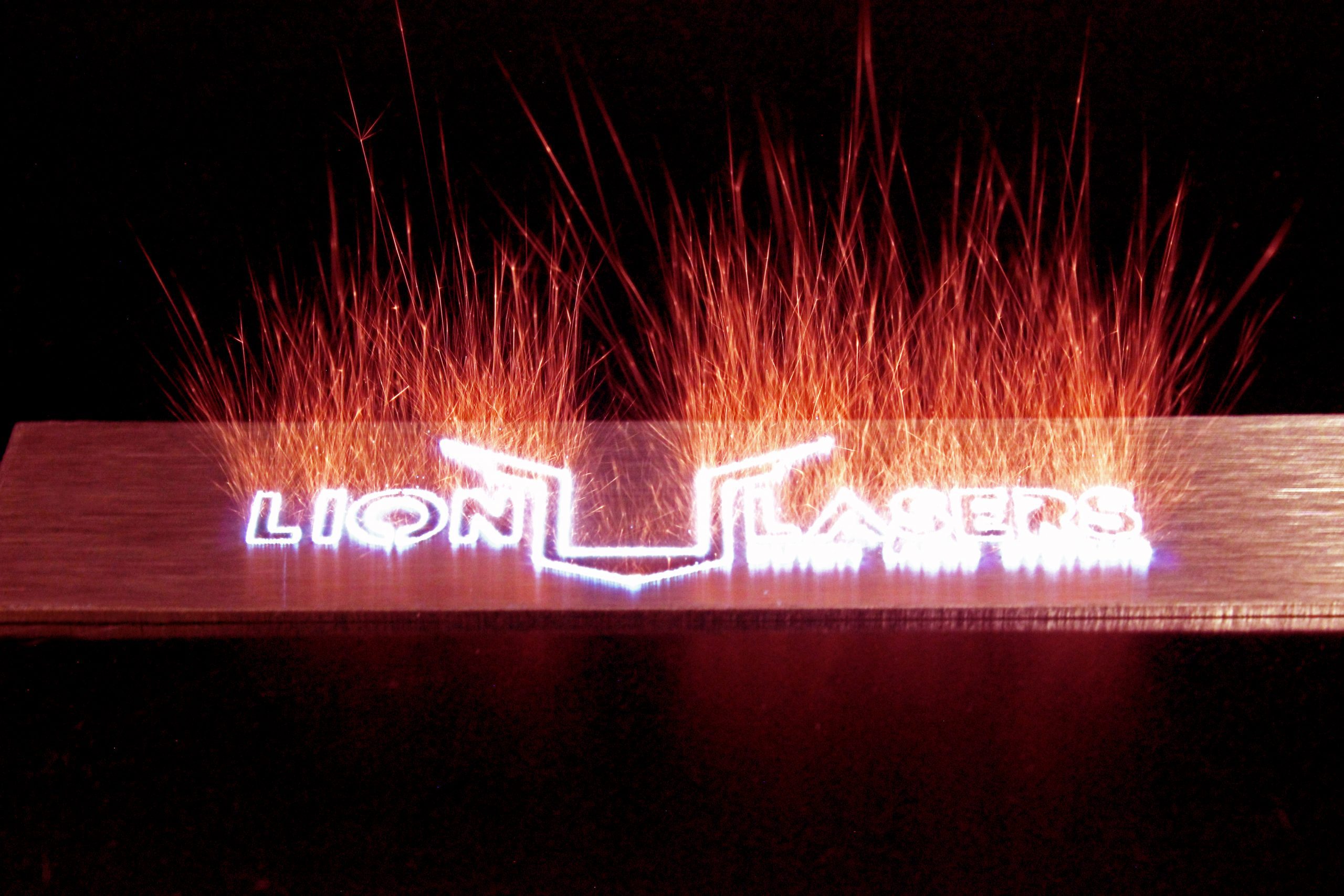

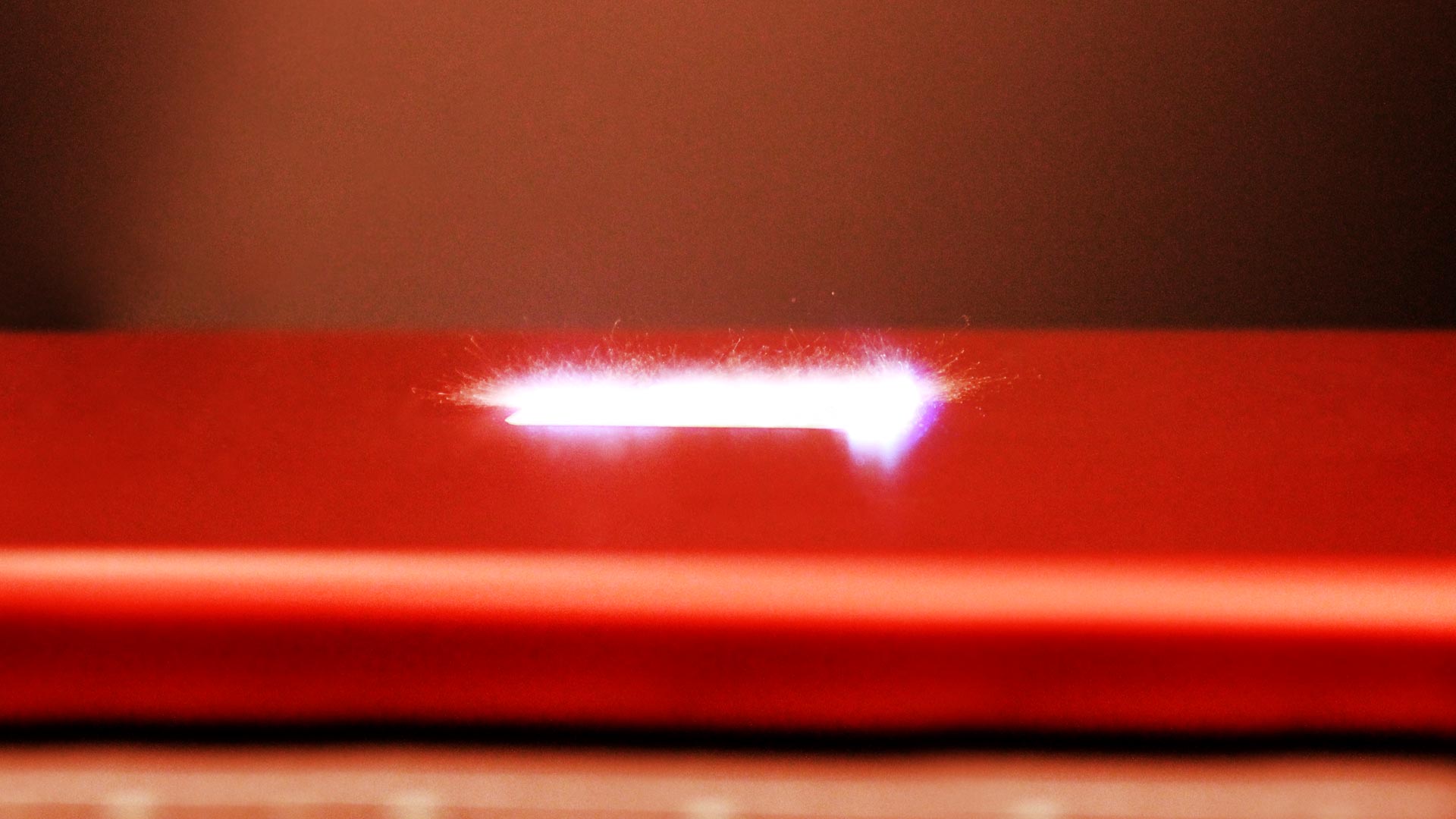

MACHINES VOOR LASERGRAVEREN,

MARKEREN EN LASERSNIJDEN

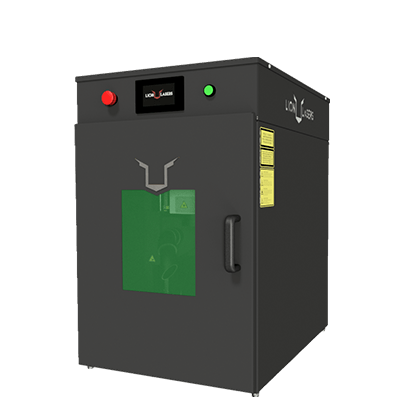

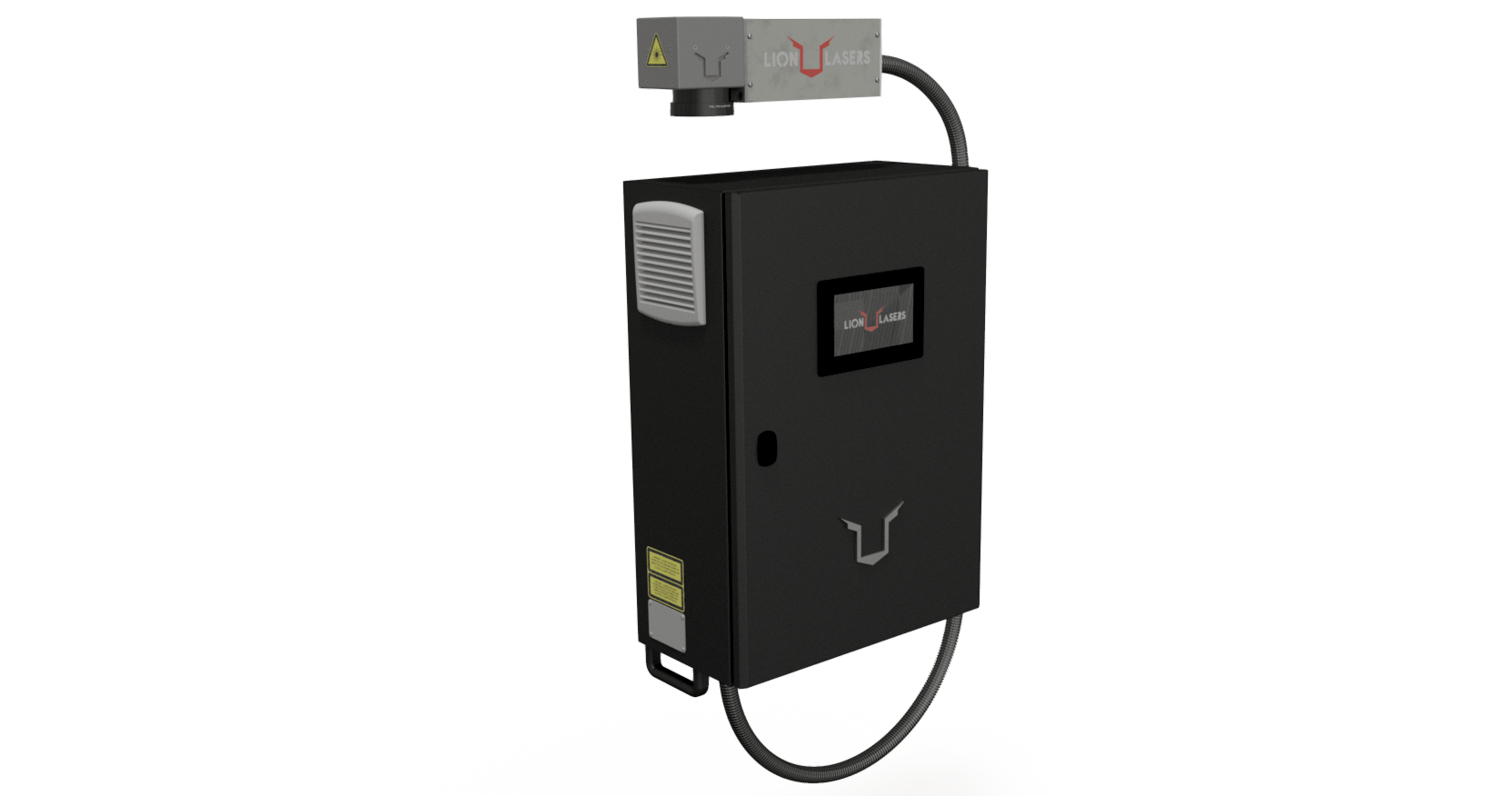

Product assortiment

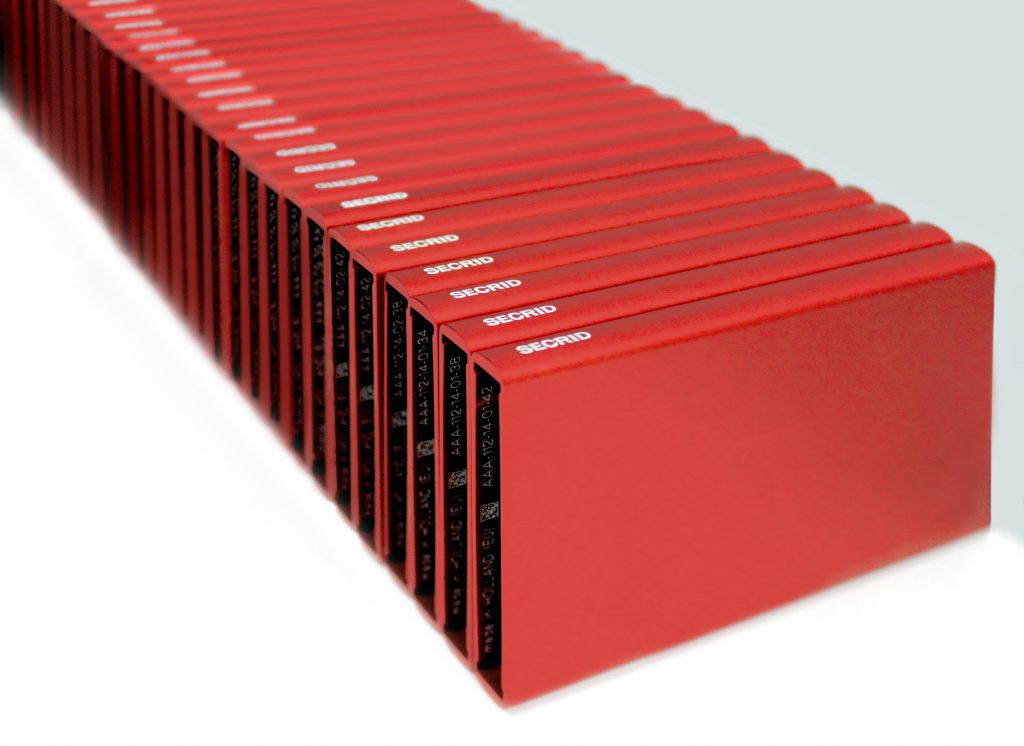

Uw product snel en nauwkeurig lasergraveren met betrouwbare en veilige lasermachines. De lasersystemen welke wij ontwerpen en bouwen, hebben het doel uw bedrijf te laten groeien. Kies hieronder een uitvoering wat voor u toepasbaar is. Mocht u niet zeker weten welke lasermachine past bij uw wensen past? Bel dan gerust of neem contact op. Wij weten vaak binnen enkele minuten wat de mogelijkheden zijn en kunnen u adviseren welk lasersysteem of machine bij uw behoeften past.

Over ons

BETROUWBAAR, VEILIG en DICHTBIJ.

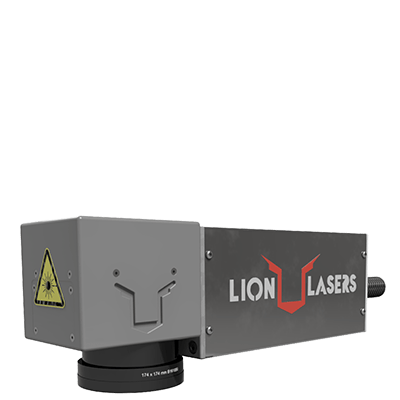

Lion lasers richt zich op de ontwikkeling, productie, verkoop en service van industriële lasersystemen. Gevoed door de praktijkkennis vanuit het lasergraveren in productie is ons bedrijf uitgegroeid tot een belangrijke speler in de lasermarkt in Nederland. Wij richten ons voornamelijk op het ontwikkelen en bouwen van lasersystemen voor graveren, coderen, snijden en lassen van diverse materialen.

ENKELE VAN ONZE WAARDEVOLLE PARTNERS

ONZE KLANTEN

Contact

Interesse? Bel of mail gerust.

Bent u nog geen klant en wenst u informatie te ontvangen over de mogelijkheden voor uw toepassing? Wanneer u het contactformulier invult wordt u gebeld door één van onze laser adviseurs.