LASER CLEANING

CLEANING OF SURFACES

EXPLANATION OF THE PROCESS

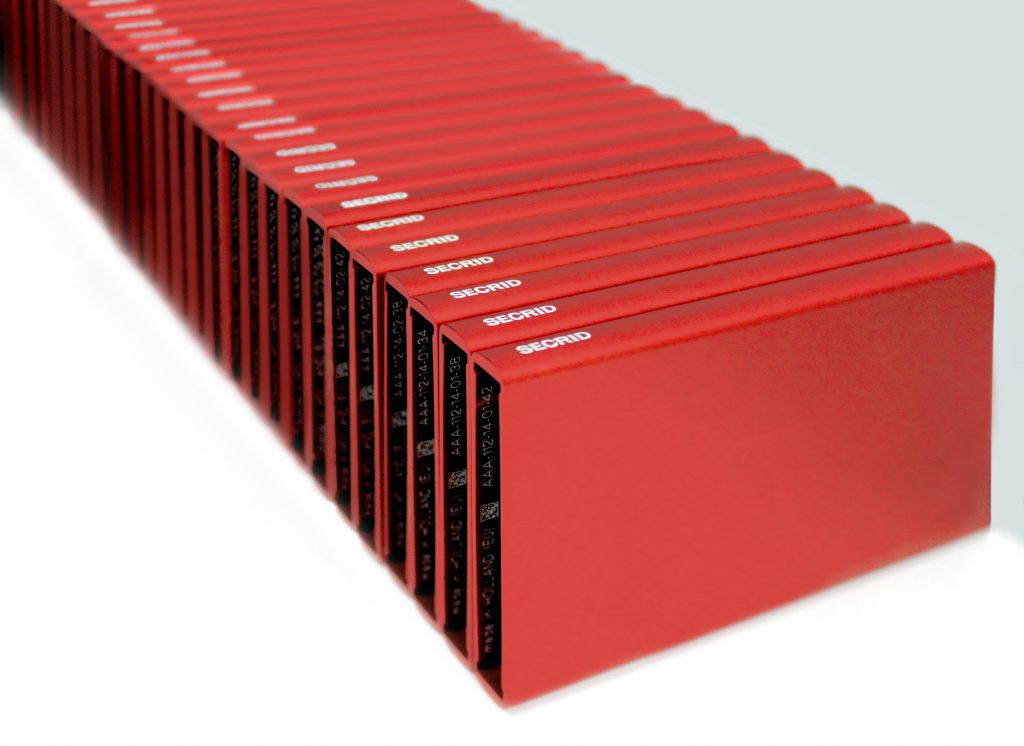

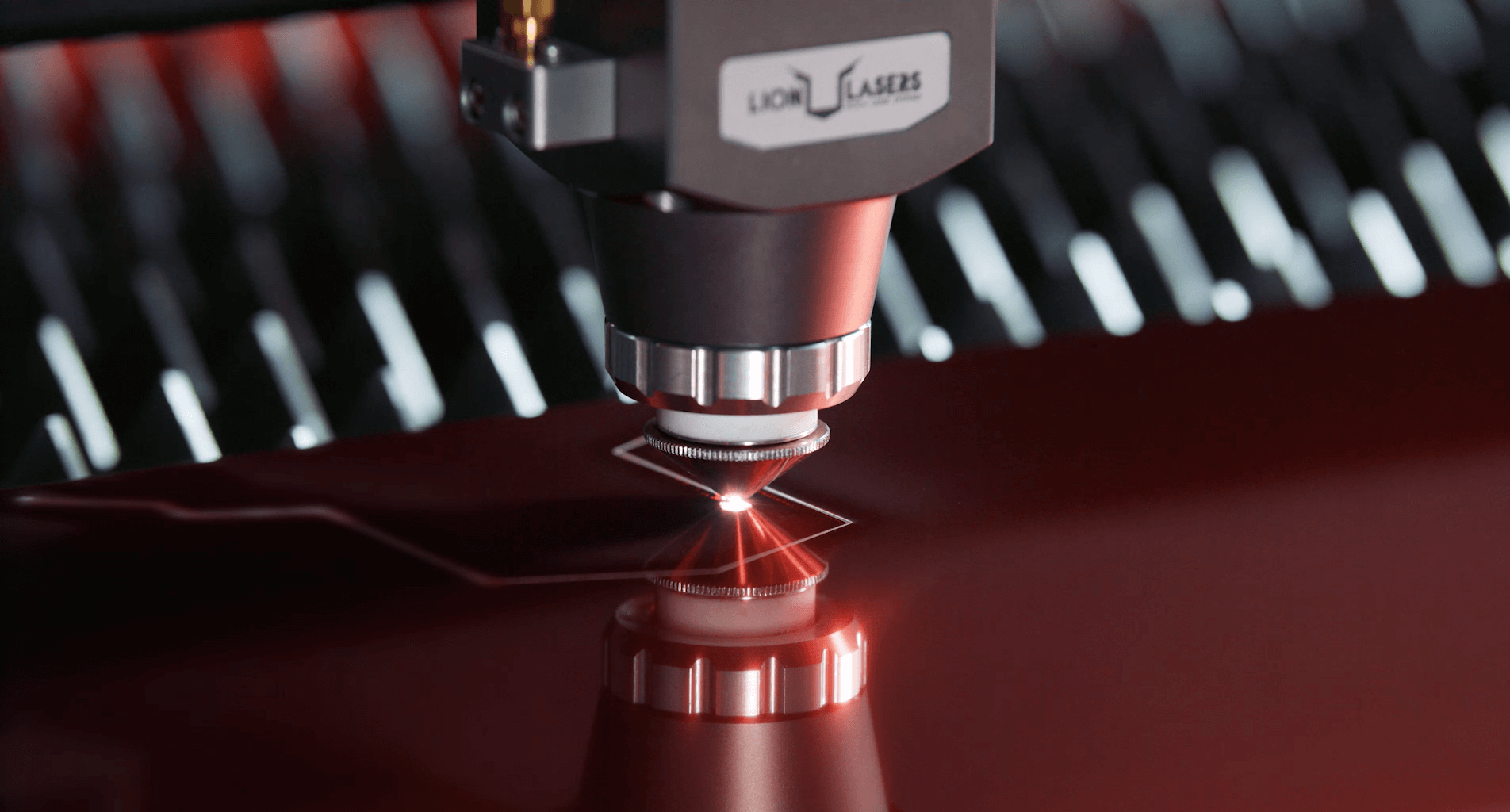

Removing rust, pre- and post-processing of welds, the pre-treatment of painting and coating processes; Lion Lasers has the mind-blowing solution to them all.

The special thing about cleaning with a laser beam is that the entire process is implemented with only the usage of light. Almost all traditional cleaning methods include adding material. Chemical cleaning, scouring and sandblasting, all leave their tracks, which can sometimes lead to a detrimental effect. As by sandblasting, rust particles can be pushed inside the material with the power of the beam. Whereas the laser beam blasts energy as an explosion to the surface of the rust particle, removing only the rust part of the material. Even with delicate cleaning, the laser is extremely well adjustable in power and pulse length. With some of the applications, you can work with setting the wavelength to a higher absorption on the pollution than the absorption of the product. While working with other applications, the energy density of the laser beam will get below the limit value of damaging the material. Cleaning with laser beams can also be used to roughen the material, resulting in a better attachment of the glue layer or coating.

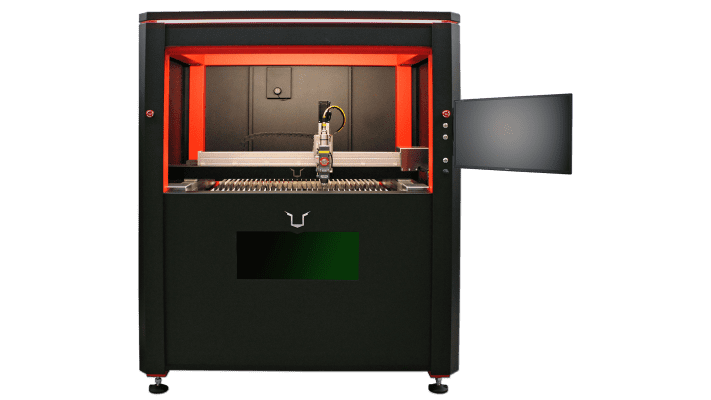

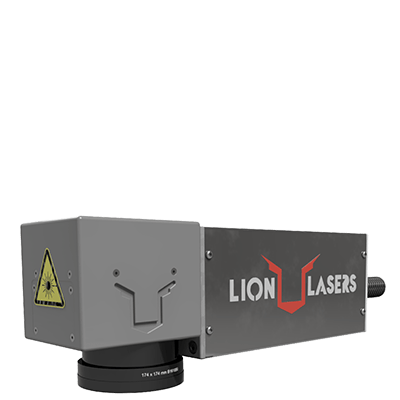

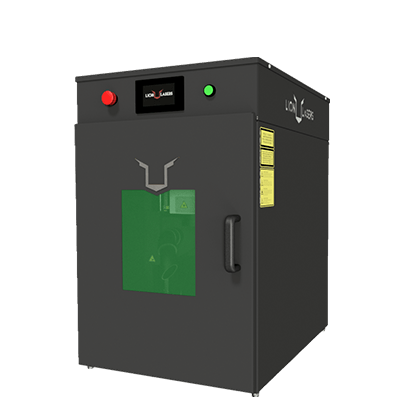

Suitable laser systems to carry out this process: