LASER CUTING

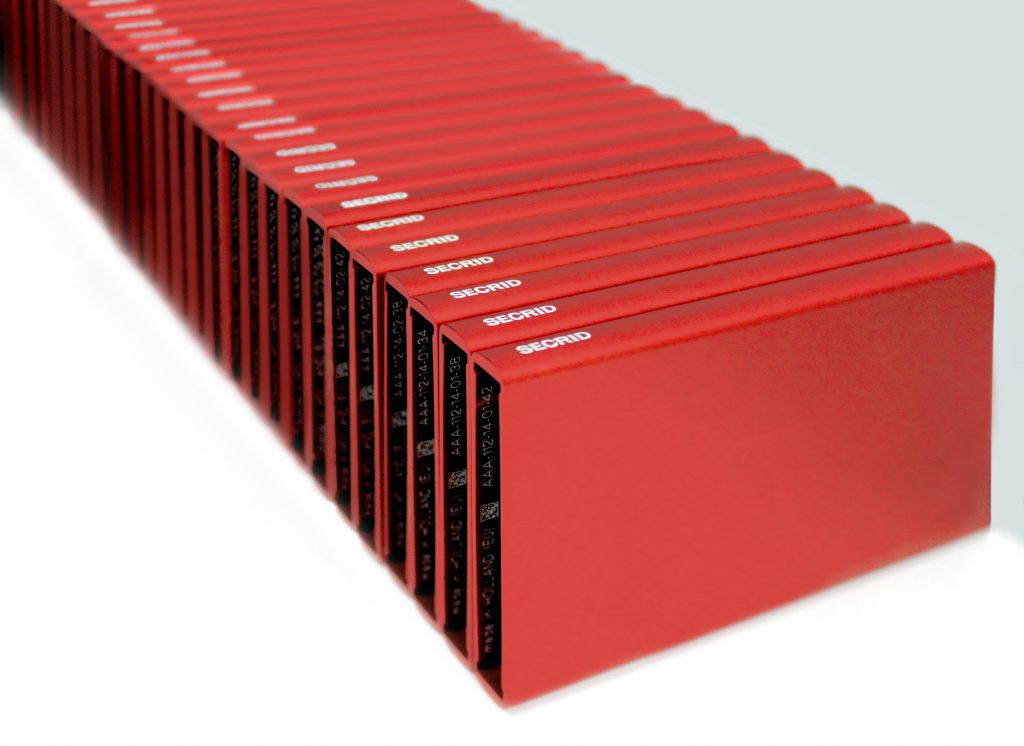

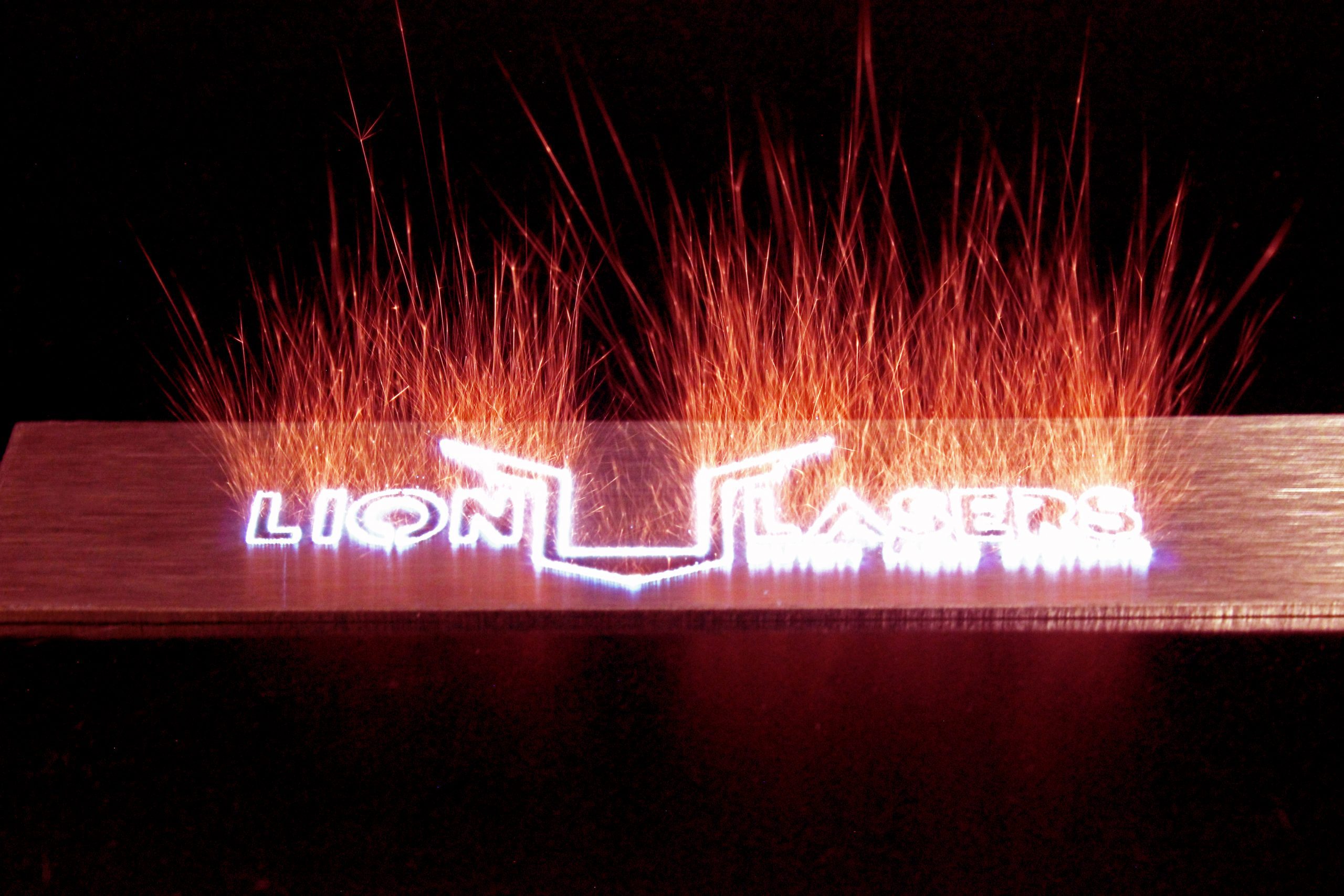

REFINED CUTTING WORK WITHOUT BURNING

EXPLANATION OF THE PROCESS

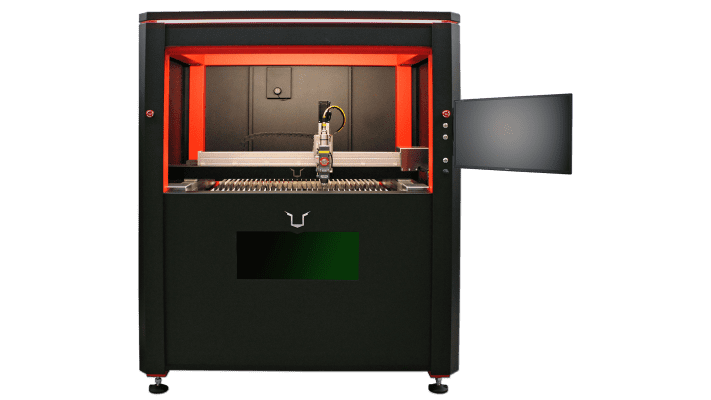

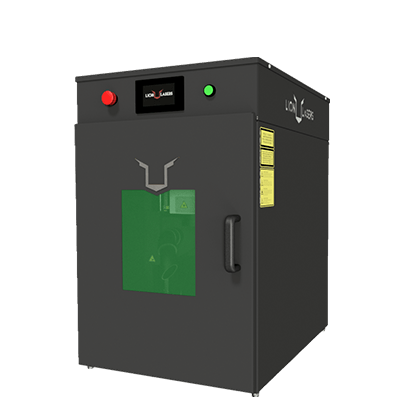

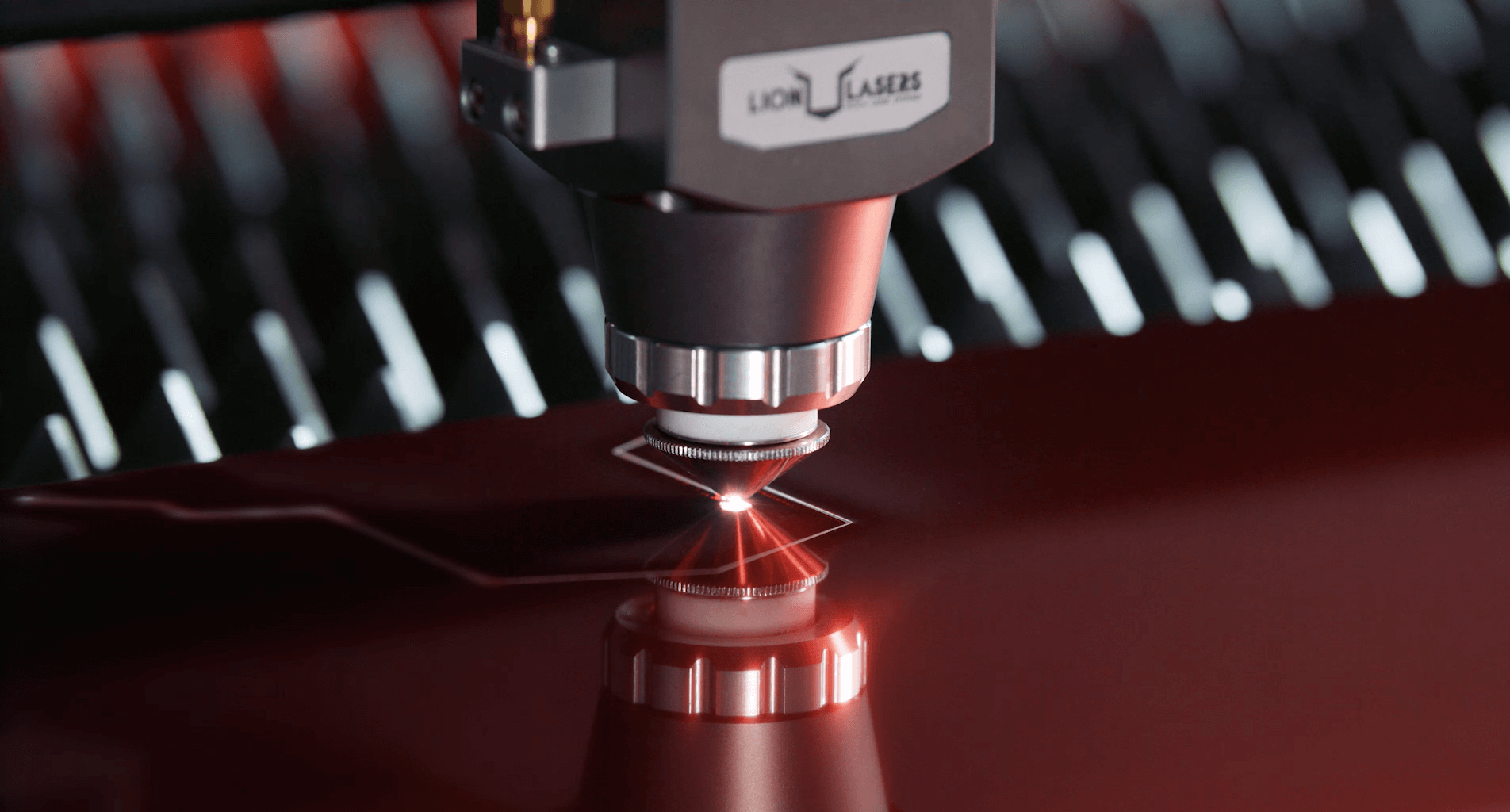

Lion Lasers designs compact, modular laser cutting machines which can cut a product accurately and lightning fast.

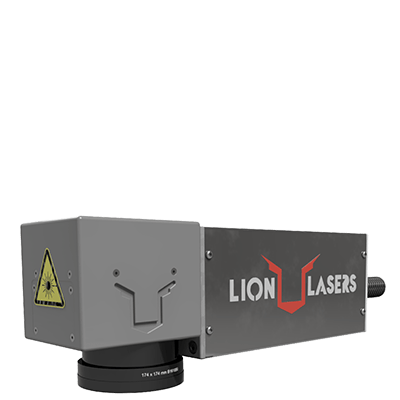

A powerful lightning beam can burn, melt or evaporate materials. Through the absorption of the laser light, the energy from the beam will be absorbed by the material. Depending on the energy density, heating, melting or even evaporation will take place. By using a smaller, more intense laser spot and a short pulse or high velocity, heat damages in other parts of the material can be prevented. A cut with as little burring as possible, can be obtained in metal by blowing high air pressure or gas along with the laser beam. Within this process, focussing on the air/gas flow is more important than the laser focussing itself. That’s why an accurate follow-up system is necessary to continually follow the surface. Cutting paper and wood also takes up the required attention, since it is desired to cut with as little combustion as possible. By cutting wood or paper rapidly, for example with a digital galvo-system, combustion can often be prevented. With a high-quality laser source and a good cutting head, many gains can be made. Very fast cutting, for example with a digital galvo system, can often also prevent soot formation when cutting paper or wood.

Suitable laser systems to carry out this process: