Lion Move

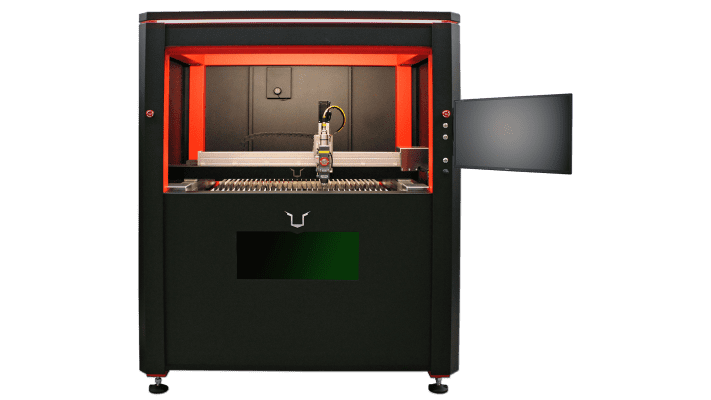

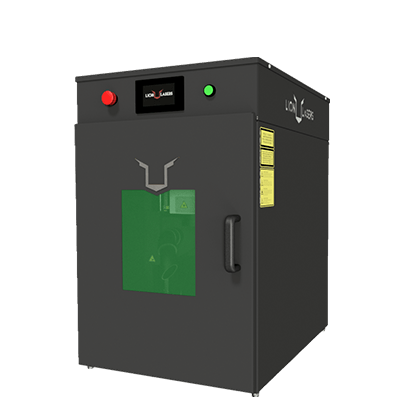

A powerful solution for the fully automated production process

The Lion Move is a product range in which we are able to code products on-the-fly. Per system, we can engrave many products per second. If necessary, Lion Lasers links different systems together to achieve even greater production. In cooperation with specialists, complete production lines are built with vision applications, robotics and product-specific automation solutions

- Engraves at high speed with the movement of the product

- Robust construction with small dimensions

- Suspension possible at various angles

- Working completely independently

- Touchscreen or remote control operation

- Multiple systems linkable

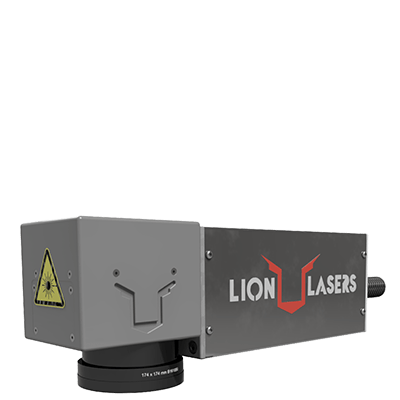

Lion Move Details

SPECIFICATIONS

| Housing | Ca. 500 x 254 x 700 mm (wxdxh) |

|---|---|

| Weight | ca. 35 kg |

| Work field | 170 x 170 mm |

| Laser head | Digital LionScan galvonaised scan head |

| Laser source | Fiber/CO2/UV |

| Wavelength | 1064 nm/10640 nm/355 nm |

| Pulse length | Depending on the laser source |

| Pulse peak | Depending on the laser source |

| Pulse frequency | Depending on the laser source |

More information

Lion Move

The Lion Move is easy to integrate into production lines and machines. Because we build the system ourselves in the Netherlands, you can count on our knowledge and support for integration in your project. The machine is quickly available as an affordable module. For special applications, we can develop and build systems to your requirements. Of course, we are happy to think along with you.

As standard, the Lion Move is available with 3 different wavelengths, allowing almost all materials to be machined. In this regard, the Lion Move Fiber is the most cost-efficient version with a huge lifetime and relatively high powers. The fibre laser is ideal for metals, engraving in printing inks on packaging and various plastics. The CO2 laser can again mark many organic materials. Even an affordable UV version is available making new applications accessible that were previously unprofitable. The UV version is very strong on “tricky” plastics such as transparent plastics and other materials that can be tricky for fibre.

Network or USB can be used to connect to the controller and templates can be created and stored on the Lion Move. In operation, the Lion Move can run the laser process independently without a connected PC. Through the touchscreen, pre-stored templates can be called up and texts can be set with a variable such as a serial number or batch code.

It is possible to quickly switch between 7 different pre-programmed files (templates) via a simple BCD signal (3 on/off commands).

Via the network connection, a pre-stored template can be called up using TCP/IP protocol and the desired texts (codes) can be customised for each product.

The Lion Move has standard connections for encoders and sensors for printing on moving objects. As accessories, we supply encoders from Sick and trigger sensors from Panasonic which already work plug and play.

Request more informationAPPLICATIONS

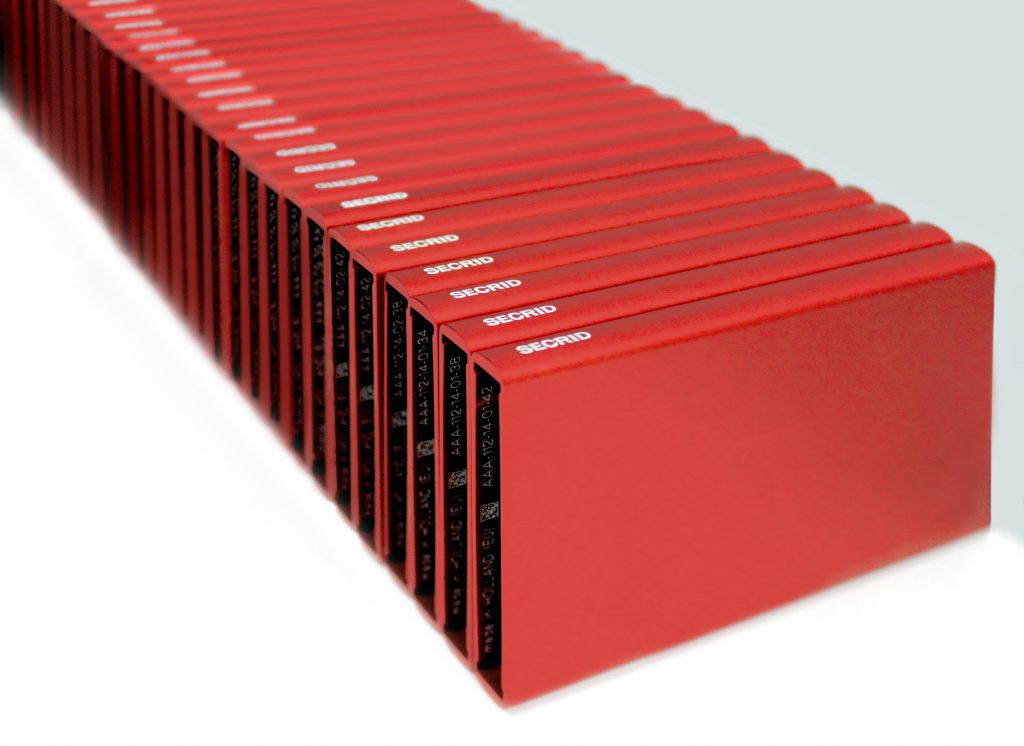

On-the-fly marking of plastic bottles

Coding THT code in packaging material

Coding THT code in packaging material

Coding eggs

Coding eggs

High-contrast coding in plastic

High-contrast coding in plastic